EnduRE30C R-E Coating Gen 7

EnduRE30C Gen 7 is a rare-earth radiative cooling coating engineered for metal substrates — Colorbond®/metal roofs, storage tanks, industrial cabinets/containers, pipelines, and outdoor utility enclosures. It combines high solar reflectance with 8–13µm atmospheric-window emission to passively drive heat away, delivering up to 30°C surface temperature reduction and 25–40% cooling energy savings. The tough fluorocarbon system provides long-term protection in harsh industrial, coastal, and high-UV environments.

Key Benefits

- ✔ Ultra-weather-resistant fluorocarbon system (UV, salt spray, acid/alkali, pollution)

- ✔ High solar & UV rejection with strong radiative cooling performance

- ✔ Up to 30°C cooler surfaces; 25–40% HVAC load reduction (site & climate dependent)

- ✔ Excellent adhesion and durability on metal structures

- ✔ Water-based, low-VOC, non-toxic; no wiring or power required

- ✔ Available in white and custom colours

Applications

- ✔ Metal / Colorbond® roofs

- ✔ Storage tanks & silos

- ✔ Industrial cabinets, containers & equipment housings

- ✔ Demountables, site cabins & temporary buildings

- ✔ Pipelines & exposed metallic infrastructure

- ✔ Power substation & telecom cabinets, EV charging cabinets

Performance Metrics

| Solar Reflectance | 92% |

| Radiant Cooling Power | 152 W/m² |

| Atmospheric Window Emissivity | 98% (8–13µm) |

System & Film Build

| Layer | Purpose | Dry Film Thickness | Recoat Time* | Dilution | Method |

|---|---|---|---|---|---|

| Primer (A) | Adhesion & anti-corrosion base | 30–60 µm | ≥4 h | Deionized water 10:1–2 | Spray/Roller/Brush |

| Functional Coat (B) | Rare-earth radiative cooling layer | 80–100 µm | ≥4 h | Deionized water 10:3 | Spray |

| Topcoat (C) | UV & weather barrier (fluorocarbon) | 15–25 µm | ≥24 h | No dilution | Spray |

*Ambient 5–35°C, RH ≤75%.

Technical Data

| Wet / Dry Film Thickness (per system) | 160–250 µm wet / 130–180 µm dry |

| Touch-Dry / Hard-Dry | ≤1 h / ≤24 h |

| Coverage | Approx. 50 m² per full 3-coat set (method & substrate dependent) |

| Application Methods | Airless/air spray, roller, brush |

| Substrate Requirements | Firm, clean, dry (moisture ≤10%), pH 7–9; remove oil/rust; abrade/etch glossy metal |

| Colours | White (standard) & custom colours |

| Kit Specification | A: 6.5 kg, B: 10 kg, C: 6 kg |

| Density | A: ~1.37 g/ml, B: ~1.74 g/ml, C: ~1.07 g/ml |

| Shelf Life | 18 months (sealed) |

| Storage | Store 5–40°C in a dry, ventilated place; keep away from heat/ignition |

Surface Preparation & Conditions

- ✔ Remove dust, oil, loose coatings; de-rust and roughen as required

- ✔ Ambient 5–35°C, RH ≤75%; ensure ventilation during application & curing

- ✔ Do not apply during rain or when rain is expected within 24 hours

Sustainability

Water-based, low-VOC formulation supports ESG and green-building goals by reducing air-conditioning demand and associated emissions through passive cooling.

Note: Values are typical for guidance. Always follow the detailed Construction/Application Manual for project-specific instructions.

Looking for exclusive distributor partners in Australia — contact us to explore opportunities.

Enquire NowRadiative Cooling Principle for Coatings

Stay Cooler, Naturally with Rare Earth Technology

Easyto’s EnduRE30C™ Rare Earth Coatings use advanced radiative cooling to keep building surfaces dramatically cooler under the sun. Unlike traditional paints that only reflect visible light, our coatings combine thermal barrier, solar reflection, and natural radiative emission for all-round heat control. This results in lower indoor temperatures, reduced HVAC loads, and improved energy efficiency.

How Radiative Cooling Works

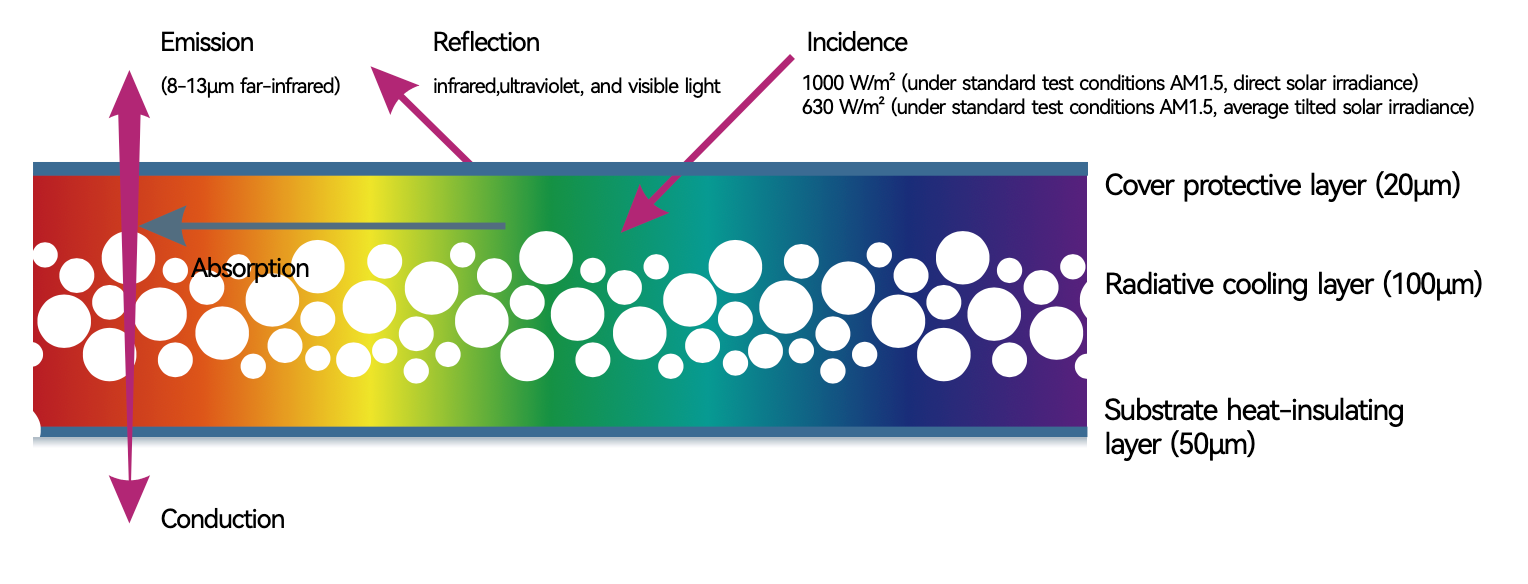

The coating structure consists of multiple functional layers: a protective surface, a rare earth radiative cooling layer, and a heat-insulating substrate. Together, these layers reflect, block, and re-radiate solar energy — ensuring surfaces stay cooler without compromising durability or aesthetics.

Three Key Mechanisms

1. Thermal Barrier

Heat conduction is reduced by using rare earth materials with low thermal conductivity, preventing excess heat from transferring indoors.

2. Thermal Reflection

The coating reflects solar radiation energy across a wide wavelength range (200–2500nm), reducing the amount of heat absorbed by the building surface.

3. Thermal Radiation

Any absorbed solar energy is re-emitted as harmless far-infrared radiation (8–13μm) back into the sky through the atmospheric window — a natural, maintenance-free cooling process.

Why Rare Earth Makes the Difference

Unlike conventional titanium-based paints, Easyto’s rare earth coatings maintain high stability, strong solar rejection, and long-term weather resistance. This ensures performance does not fade with time and continues to deliver measurable energy savings year after year.

Real-World Benefits

- ✔ Surface temperature reduction up to 30°C

- ✔ Indoor cooling by 5–11°C

- ✔ 25–40% reduction in air conditioning energy load

- ✔ Longer service life with no yellowing or chalking

- ✔ Passive, maintenance-free cooling

Applications

Radiative cooling coatings are ideal for metal roofs, warehouses, demountable, telecom cabinets, tanks, animal barns, and more. By staying cooler naturally, these coatings extend material lifespan, improve occupant comfort, and lower operating costs.

EnduRE30C™ R-E Coating Warranty

Applicable to: EnduRE30C™ Gen 5 & Gen 7

Version: 1.0 | Effective: Sep 2025 | ABN: 41 688 512 138

Easyto Thermal Solution Australia Pty Ltd (“Easyto”) provides this Limited Warranty for EnduRE30C™ R-E Coating Gen 5 and Gen 7, when applied by an Authorised Applicator on approved substrates in Australia.

Warranty Period

The EnduRE30C™ R-E Coating is warranted for 8 years from the installation date when applied on qualified substrates (e.g., concrete, metal, compliant roofing) by an Authorised Applicator.

What’s Covered

- No cracking, fissuring, or peeling not caused by external force or substrate failure

- No significant insulation performance drop (>30% vs initial data, verified by testing)

- No large-area delamination or blistering (not caused by pollution or corrosion)

- No abnormal fading or discolouration (beyond “slight fading” as per standards)

Exclusions

- Normal wear and tear (minor scratches, gloss reduction)

- Improper maintenance (harsh cleaners, lack of upkeep)

- External forces (impacts, fire, flooding, accidents, unauthorised contractors)

- Substrate issues (pre-existing cracks, leaks, deformation)

- Use in unsuitable environments (strong acid/alkaline, high industrial pollution)

How to Make a Claim

- Contact your Authorised Applicator with proof of purchase.

- If unavailable, email info@easyto.com.au with subject “Warranty”.

- Include proof of purchase, installation date, defect photos, and applicator details.

- Provide access for inspection. Unauthorised repairs void coverage.

Australian Consumer Law

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law (ACL). You are entitled to a replacement or refund for a major failure and compensation for reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if they fail to be of acceptable quality and the failure does not amount to a major failure. The benefits of this warranty are in addition to your ACL rights.

Contact

Easyto Thermal Solution Australia Pty Ltd

ABN: 41 688 512 138

Email: info@easyto.com.au

Phone: 0478 584 880