EnduRE30C Reflect™ Radiative Cooling Coating for Steel Roofing

EnduRE30C Reflect™ Radiative Cooling Coating for Steel Roofing is a cost-effective rare earth–based reflective cooling coating specifically developed for corrugated steel roofing sheets and steel roofing tiles, including colour steel and Colorbond®-type profiles. By reflecting solar radiation, Reflect™ helps reduce roof surface heat build-up and internal heat gain in large, lightweight roof structures.

Designed as a simplified two-layer system, EnduRE30C Reflect™ focuses on pure reflective thermal performance. It does not include waterproofing or hydrophobic functionality, making it suitable for applications where heat reduction is required but water repellency is not critical.

Best For

- Corrugated steel roofing sheets and roofing tiles

- Colour steel and Colorbond®-type metal roofs

- Animal barns and livestock shelters

- Agricultural buildings and farm structures

- Warehouses, sheds and lightweight industrial buildings

- Cost-sensitive projects requiring basic heat reduction

Key Benefits

- High solar reflectance to reduce roof surface temperature

- Derived from Easyto rare earth cooling material technology

- Simplified two-layer coating system

- Lower material and application cost compared to advanced systems

- Strong adhesion to properly prepared steel roofing substrates

- Improves thermal comfort in non-air-conditioned spaces

- Water-based, low VOC formulation

Applications

EnduRE30C Reflect™ is suitable for:

- Steel roofs where insulation upgrades are limited

- Facilities where waterproofing is handled separately

- Projects prioritising affordability over advanced performance

- Large roof areas requiring economical heat reduction

System Overview

EnduRE30C Reflect™ is a two-layer professional cooling coating system consisting of a primer and a functional reflective layer. It is designed to provide solar reflectance–based heat reduction without a protective topcoat.

- Layer A: Primer for adhesion to steel roofing substrates

- Layer B: Functional reflective cooling layer

Important Notes

- This product provides cooling performance only.

- It is not designed to replace waterproof membranes or corrosion protection systems.

- Steel roofing surfaces must be clean, dry and properly prepared before application.

- Actual performance may vary depending on roof profile, environment and application quality.

EnduRE30C Reflect™ is an economical cooling solution for corrugated steel roofing, delivering practical heat reduction where water repellency is not a critical requirement.

Looking for exclusive distributor partners in Australia — contact us to explore opportunities.

Enquire Now✨ Performance Highlights

| Property | Result |

|---|---|

| Solar Reflectance | 92% |

| Radiant Cooling Power | 152 W/m² |

| Atmospheric Window Emissivity | 98% (8–13µm) |

⚙️ Technical Specifications

| Specification | Detail |

|---|---|

| System | Two-layer reflective cooling coating |

| Coverage Area | Approx. 50 m² per set |

| Shelf Life | 18 months (sealed, stored at 5–40°C) |

EnduRE30C Reflect™ for Steel Roofing

This page provides practical guidance for applying EnduRE30C Reflect™ Radiative Cooling Coating for Steel Roofing, a cost-effective rare earth–based reflective cooling system designed for corrugated steel roofing sheets and steel roofing tiles, including color steel and Colorbond®-type profiles. For detailed procedures and project-specific requirements, always refer to the official Construction Manual.

1) Application Methods

- Airless spray (recommended for uniform film build and coverage)

- Air spray

- Roller or brush (limited to small areas, edges, touch-ups and repairs)

2) Drying & Recoat Time

Drying and recoat times depend on temperature, humidity, airflow and substrate condition. Under standard conditions, typical guidance is as follows:

- Surface dry: approximately ≤ 1 hour

- Hard dry: approximately ≤ 24 hours

- Minimum recoat time: 4 hours

- Maximum recoat window: up to 24 hours

Reference conditions: ambient temperature 5–35°C, relative humidity ≤ 75% RH.

3) Application Conditions

- Steel roofing substrates must be sound, clean and dry, free from oil, grease, salt, dust and loose coatings.

- Remove rust, scale and oxidation by mechanical cleaning or abrasion prior to coating.

- Substrate moisture content: ≤ 10%

- Substrate pH: neutral range (pH 7–9)

- Application temperature: 5–35°C

- Relative humidity: ≤ 75% RH

- Ensure adequate ventilation in enclosed or confined spaces during application and curing.

4) System & Dilution Guidance

EnduRE30C Reflect™ is a two-layer coating system consisting of a primer and a functional reflective layer. No protective topcoat is included in this system.

Dilution may be required depending on application method and environmental conditions. Where dilution is used, it should be carried out with deionised water.

Important: Exact dilution ratios and layer-specific guidance vary by component and application method. Always follow the Construction Manual and project specifications to achieve the intended performance.

5) Professional Use Notice

- EnduRE30C Reflect™ is designed for professional application.

- Surface preparation quality is critical to adhesion and performance.

- This product provides reflective cooling performance only and does not include waterproof or hydrophobic protection.

- Actual coverage, drying time and thermal performance may vary depending on substrate condition, environment and application technique.

- Always conduct a small-area test and comply with site safety requirements, including appropriate PPE and ventilation.

EnduRE30C Reflect™ is a practical solution for steel roofing applications where heat reduction is required and water repellency is not a critical requirement.

Radiative Cooling Principle for Coatings

Stay Cooler, Naturally with Rare Earth Technology

Easyto’s EnduRE30C™ Rare Earth Coatings use advanced radiative cooling to keep building surfaces dramatically cooler under the sun. Unlike traditional paints that only reflect visible light, our coatings combine thermal barrier, solar reflection, and natural radiative emission for all-round heat control. This results in lower indoor temperatures, reduced HVAC loads, and improved energy efficiency.

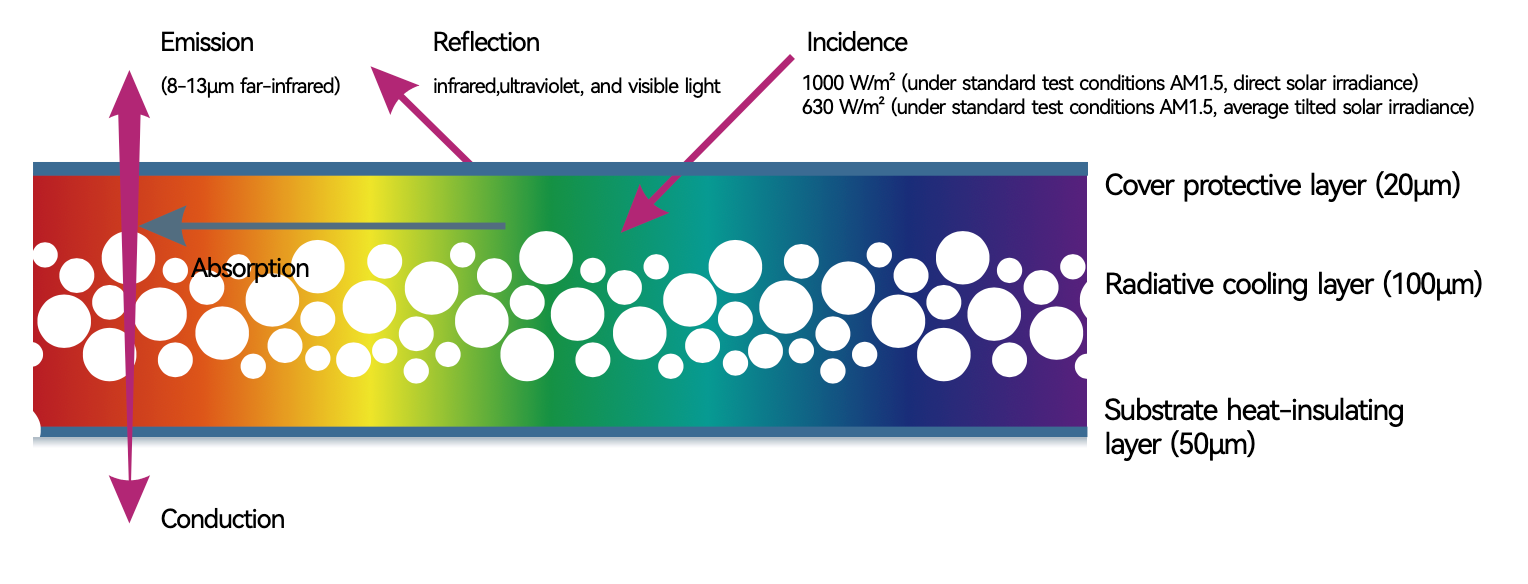

How Radiative Cooling Works

The coating structure consists of multiple functional layers: a protective surface, a rare earth radiative cooling layer, and a heat-insulating substrate. Together, these layers reflect, block, and re-radiate solar energy — ensuring surfaces stay cooler without compromising durability or aesthetics.

Three Key Mechanisms

1. Thermal Barrier

Heat conduction is reduced by using rare earth materials with low thermal conductivity, preventing excess heat from transferring indoors.

2. Thermal Reflection

The coating reflects solar radiation energy across a wide wavelength range (200–2500nm), reducing the amount of heat absorbed by the building surface.

3. Thermal Radiation

Any absorbed solar energy is re-emitted as harmless far-infrared radiation (8–13μm) back into the sky through the atmospheric window — a natural, maintenance-free cooling process.

Why Rare Earth Makes the Difference

Unlike conventional titanium-based paints, Easyto’s rare earth coatings maintain high stability, strong solar rejection, and long-term weather resistance. This ensures performance does not fade with time and continues to deliver measurable energy savings year after year.

Real-World Benefits

- ✔ Surface temperature reduction up to 30°C

- ✔ Indoor cooling by 5–11°C

- ✔ 25–40% reduction in air conditioning energy load

- ✔ Longer service life with no yellowing or chalking

- ✔ Passive, maintenance-free cooling

Applications

Radiative cooling coatings are ideal for metal roofs, warehouses, demountable, telecom cabinets, tanks, animal barns, and more. By staying cooler naturally, these coatings extend material lifespan, improve occupant comfort, and lower operating costs.

EnduRE30C™ R-E Coating Warranty

Applicable to: EnduRE30C™ Gen 5 & Gen 7

Version: 1.0 | Effective: Sep 2025 | ABN: 41 688 512 138

Easyto Thermal Solution Australia Pty Ltd (“Easyto”) provides this Limited Warranty for EnduRE30C™ R-E Coating Gen 5 and Gen 7, when applied by an Authorised Applicator on approved substrates in Australia.

Warranty Period

The EnduRE30C™ R-E Coating is warranted for 8 years from the installation date when applied on qualified substrates (e.g., concrete, metal, compliant roofing) by an Authorised Applicator.

What’s Covered

- No cracking, fissuring, or peeling not caused by external force or substrate failure

- No significant insulation performance drop (>30% vs initial data, verified by testing)

- No large-area delamination or blistering (not caused by pollution or corrosion)

- No abnormal fading or discolouration (beyond “slight fading” as per standards)

Exclusions

- Normal wear and tear (minor scratches, gloss reduction)

- Improper maintenance (harsh cleaners, lack of upkeep)

- External forces (impacts, fire, flooding, accidents, unauthorised contractors)

- Substrate issues (pre-existing cracks, leaks, deformation)

- Use in unsuitable environments (strong acid/alkaline, high industrial pollution)

How to Make a Claim

- Contact your Authorised Applicator with proof of purchase.

- If unavailable, email info@easyto.com.au with subject “Warranty”.

- Include proof of purchase, installation date, defect photos, and applicator details.

- Provide access for inspection. Unauthorised repairs void coverage.

Australian Consumer Law

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law (ACL). You are entitled to a replacement or refund for a major failure and compensation for reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if they fail to be of acceptable quality and the failure does not amount to a major failure. The benefits of this warranty are in addition to your ACL rights.

Contact

Easyto Thermal Solution Australia Pty Ltd

ABN: 41 688 512 138

Email: info@easyto.com.au

Phone: 1800 2800 41