Smart4OEM™ - Laminated Interlayer

Smart4OEM™ is an innovative rare earth thermal insulation interlayer engineered for laminated glass production. Available in both PVB and EVA formats, it preserves the core benefits of safety/anti-shatter and acoustic damping—while leveraging rare-earth 4f orbital resonance to enhance thermal insulation and UV resistance for high-performance glazing.

Key Benefits

- 🛡 Safety Lamination: Explosive-proof/anti-shatter performance inherent to PVB/EVA for safer glazing

- ☀ UV & Heat Control: Rare-earth formulation delivers ≥99% UV rejection and strong IR blocking for cooler interiors

- 🔇 Acoustic Comfort: Interlayer reduces sound transmission for quieter spaces

- 🏗 OEM-Ready: Compatible with standard lamination processes (PVB/EVA) for architectural and specialty glass

Performance Features

- 🔬 Rare-Earth Enhancement: 4f orbital resonance aids IR shielding while maintaining visible clarity

- 🌞 High Daylight: 68% ±2 visible light transmittance keeps spaces bright and natural

- 🛡 UV Protection: ≥99% UV rejection helps protect interiors and finishes

- 🔥 IR Rejection: 95% infrared rejection for improved thermal comfort

Applications

- ✔ Laminated architectural glass (facades, curtain walls, skylights)

- ✔ Noise-sensitive projects (hotels, offices, transit hubs)

- ✔ Safety glazing where anti-shatter is essential

- ✔ Western-exposed or high-solar-gain glazing

Technical Specifications

| Visible Light Transmittance | 68 ± 2% |

| UV Rejection | ≥ 99% |

| Infrared Rejection | 95% |

| Total Solar Energy Rejection | 51 ± 2% |

| Interlayer Thickness | 0.76 mm |

Smart4OEM™—engineered for OEM laminators who need safety, clarity, and thermal performance in one advanced PVB/EVA interlayer.

Looking for exclusive distributor partners in Australia — contact us to explore opportunities.

Enquire Now✨ Performance Highlights

| Property | Result |

|---|---|

| Visible Light Transmission | 68±2 (68.4)% |

| Visible Light Reflectance (Inward) | 7±2 (7.1)% |

| Visible Light Reflectance (Outward) | 7±2 (7.4)% |

| UV Blocking Rate | ≥99 (99.5)% |

| Infrared Blocking Rate | ≥95 (96.7)% |

| Total Solar Energy Rejected | 51±2 (51.3)% |

⚙️ Technical Specifications

| Specification | Detail |

|---|---|

| Thickness | 0.76mm |

| Roll Size | 2.44 x 100m /roll |

| Base Material | PVB or EVA |

| Warranty Period | 10 Years |

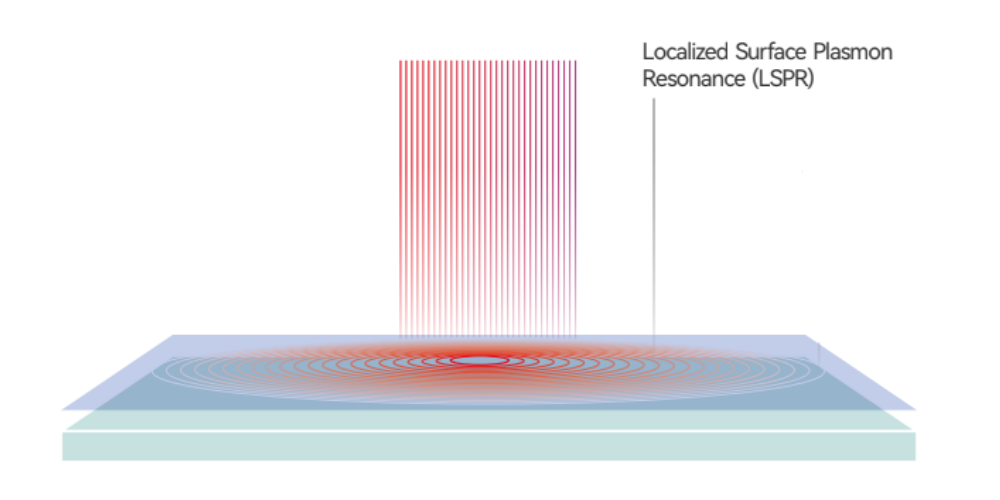

LSPR Effect

How Rare Earth Nanotechnology Controls Heat and Light

What is LSPR?

Localized Surface Plasmon Resonance (LSPR) is the principle that powers Easyto’s rare earth window films. By using Lanthanum (La), these films resonate with solar infrared (IR) and ultraviolet (UV) radiation, blocking unwanted heat while maintaining high visible light clarity.

Unlike coatings for walls or roofs, LSPR is specifically effective when applied to transparent glass surfaces. This makes it the core technology behind our architectural and automotive films.

The Three Stages of LSPR

1. Blocking Harmful Radiation

Rare earth nanomaterials block up to 95–99% of incoming infrared and ultraviolet rays while allowing visible light to pass through, ensuring both comfort and clarity.

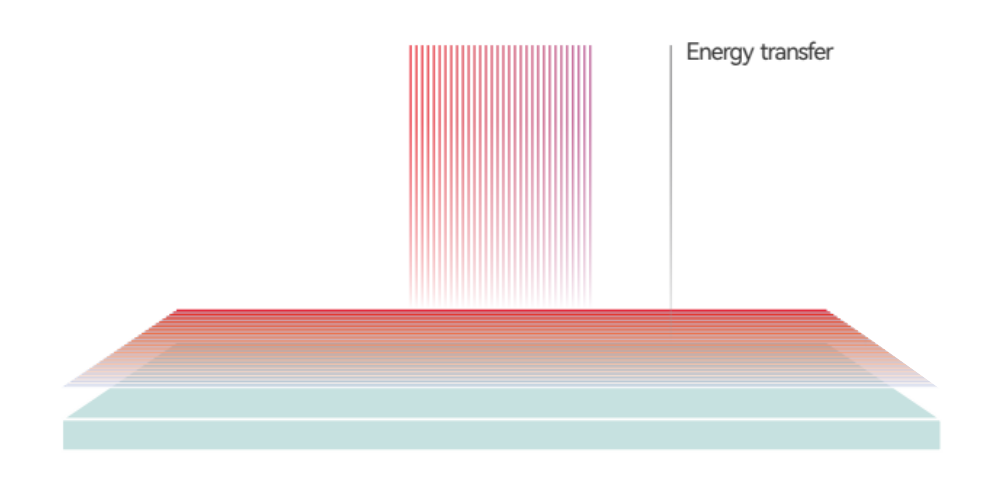

2. Converting Radiant Energy into Heat

When infrared and UV reach the Lanthanum (La) nanolayer, the film enters LSPR and absorbs/damps the radiation. That energy is then released as heat at the glass/film surface and carried away by natural air movement and conduction within the pane—rather than being transmitted indoors. Visible light still passes, keeping the glass clear while reducing solar heat gain.

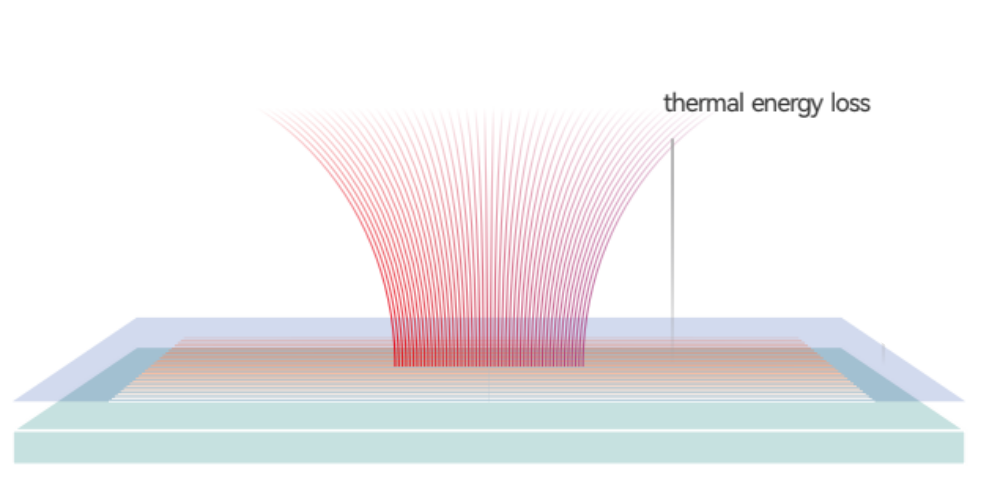

3. Dual Thermal Performance

By controlling solar heat gain in summer and retaining warmth in winter, Easyto’s rare earth coatings and films provide dual seasonal benefits. This means lower cooling costs in hot months and improved comfort during colder months—all without active energy consumption.

Why LSPR is Different

Traditional Low-E glass relies on thin metallic layers that degrade and lose effectiveness over time. Easyto’s rare earth nanotechnology, powered by Lanthanum-based LSPR, delivers:

- ✔ Stable performance without oxidation or fading

- ✔ Superior heat and UV rejection

- ✔ High visible light clarity for natural daylight

- ✔ Sustainable energy savings with no wiring or maintenance

From Science to Real-World Benefits

LSPR resonance is at the heart of Easyto’s SmartShield™ architectural films and Quantum™ automotive films. By harnessing the unique interaction of Lanthanum with solar radiation, our films provide superior comfort, UV protection, and energy efficiency without altering the clarity of glass.